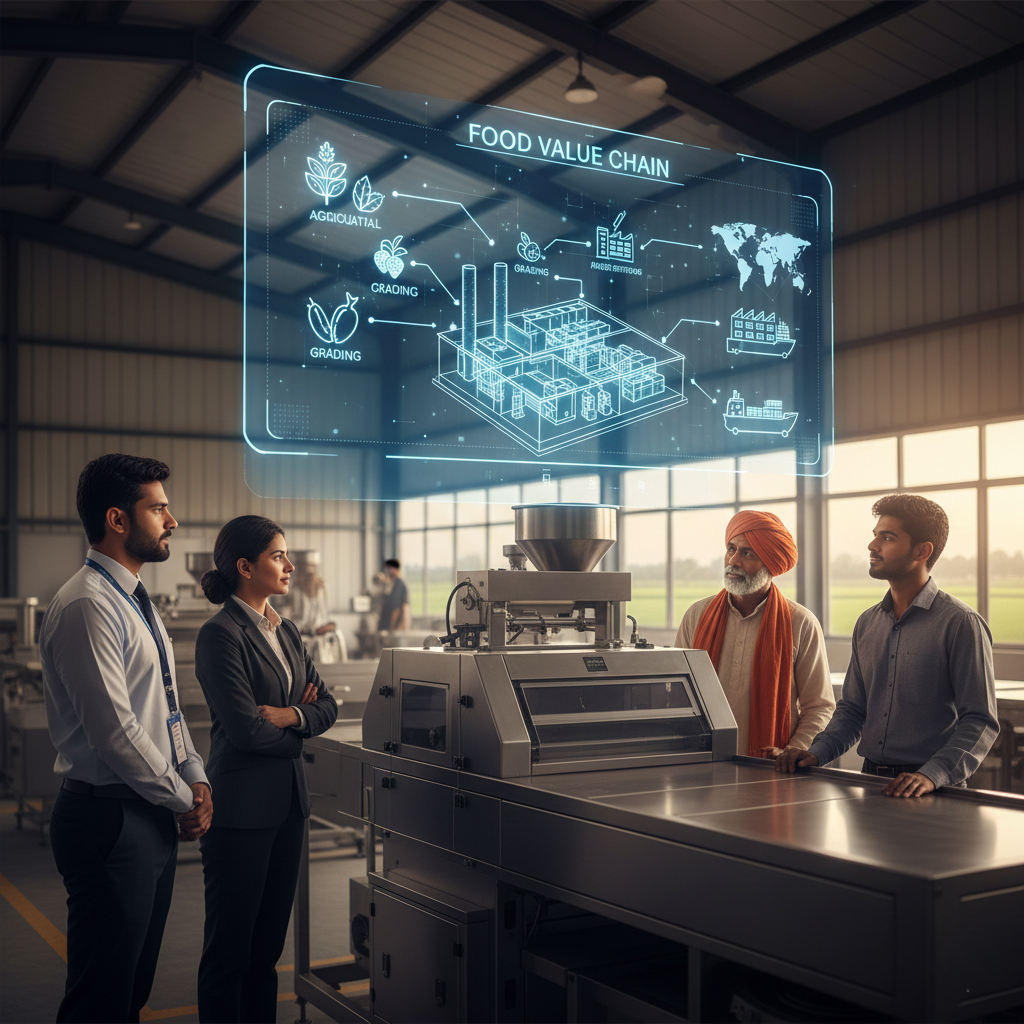

Primary Processing: The Backbone of the Food Value Chain

Primary food processing is the foundation of the food processing industry, where raw agricultural produce is converted into clean, graded, safe, and market-ready commodities. This stage is essential for reducing post-harvest losses, improving storage life, ensuring quality consistency, and enabling downstream value addition.

Primary processing units play a crucial role in:

- Strengthening farm-to-market linkages

- Improving price realisation for farmers

- Enabling exports through quality compliance

- Supporting secondary and tertiary food industries

At C2EX Consulting, we help entrepreneurs, MSMEs, FPOs, cooperatives, and agri-businesses establish technically sound, subsidy-linked, and scalable primary processing units across India.

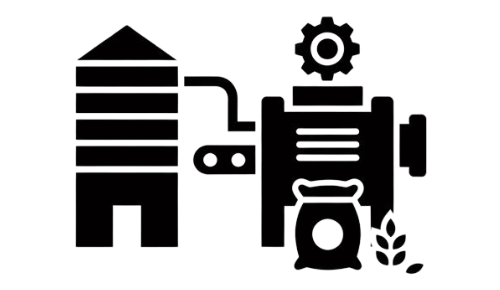

Primary Food Processing Units – Setup & Consulting Services

-

Rice mills (raw, boiled, parboiled)

-

Flour mills (wheat, maize, millet, multigrain)

-

Cleaning, de-stoning, grading & milling

-

Grain fortification (iron, folic acid, vitamins)

-

Bulk storage silos & retail packaging

Applications: Domestic consumption, institutional supply, exports

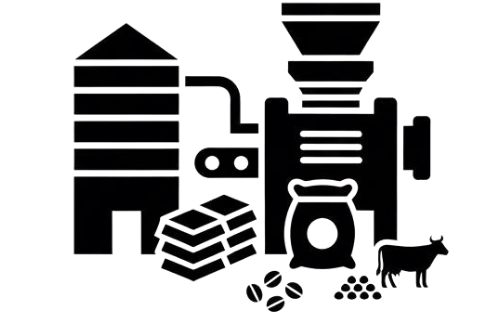

-

Dal milling, splitting & polishing

-

Colour sorting & grading

-

Husk and by-product utilisation (cattle feed)

-

Bulk & retail packing solutions

Applications: Retail, institutional kitchens, export markets

-

Cleaning, drying & grinding

-

Blending and formulation of spice mixes

-

Cryogenic grinding for aroma, colour & oil retention

-

Steam sterilisation & export-grade packaging

Applications: Domestic brands, bulk supply, exports (EU, US, GCC)

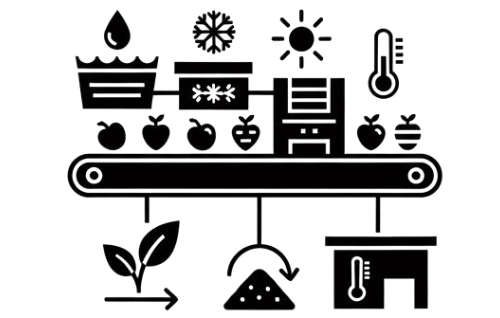

-

Sorting, washing & grading lines

-

Pulping, dehydration, freezing & minimal processing

-

Cold storage, ripening chambers & logistics integration

-

Waste utilisation (peels, pomace, compost)

Applications: Fresh market supply, food processors, exports

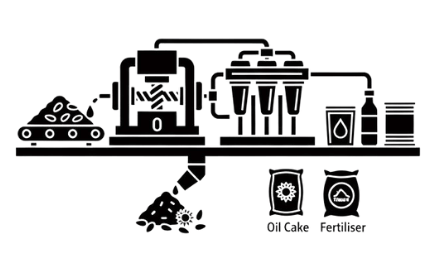

-

Edible oil extraction (groundnut, mustard, sesame, sunflower, coconut)

-

Expellers, filtration & refining

-

Packaging (pouches, bottles, tins)

-

Oil cake utilisation for feed & fertilisers

Applications: Retail oils, bulk buyers, export markets

Our End-to-End Consulting Services

Feasibility Study & Detailed Project Report (DPR)

-

Commodity assessment & sourcing analysis

-

Capacity planning & technology selection

-

CAPEX, OPEX, ROI & break-even analysis

-

Bankable DPR for loans & funding

Government Subsidy & Scheme Assistance

-

We assist in identifying, applying, and securing benefits under:

-

MOFPI / PMFME

-

APEDA

-

MSME / FPO / Cooperative incentives

-

End-to-end handholding until approval & disbursement.

Licensing & Regulatory Compliance

-

FSSAI licensing & documentation

-

ISO, HACCP & GMP compliance

-

Pollution Control Board approvals

-

Export compliance (APEDA, EU, USFDA where applicable)

Plant Layout & Infrastructure Planning

-

Hygienic plant layout as per food safety norms

-

Material & people flow optimisation

-

Utilities planning (power, water, steam, waste handling)

-

Provision for future expansion

Machinery Selection & Customisation

-

Technology benchmarking & vendor evaluation

-

Machinery customisation for capacity & budget

-

Installation & commissioning support

-

Performance validation & trials

Quality Assurance & Shelf-Life Support

-

SOP development for processing & hygiene

-

Quality checkpoints & CCP definition

-

Shelf-life evaluation & lab testing support

-

Packaging material selection

Export Readiness & Market Support

-

Export documentation & certifications

-

Packaging & labelling compliance for global markets

-

Guidance on buyer expectations & quality benchmarks

Fuelling your business ambitions with our driving force

Who Can Benefit from Primary Processing Units?

-

Individual entrepreneurs

-

Farmer Producer Organisations (FPOs)

-

Cooperatives & SHGs

-

Agri-startups

-

MSMEs & exporters

Why Choose C2EX Consulting?

-

Deep expertise in agro & food processing

-

Proven experience across commodities

-

Strong understanding of subsidy frameworks

-

Integrated technical, regulatory & commercial support

-

Customised solutions for micro, small & large units

Client Success Story

A spice processing entrepreneur from Karnataka aimed to scale operations for domestic and export markets.

C2EX Consulting delivered:

-

A bankable DPR securing 30% MOFPI subsidy

-

FSSAI & export compliance support

-

Cryogenic grinding process design for premium quality

Result: The unit successfully commenced exports to Europe and the Middle East, with improved margins and quality consistency.

OUR SATISFIED CUSTOMERS

Frequently Asked Questions (FAQ)

- Primary processing: Cleaning, grading, milling, basic processing

- Secondary processing: Value-added products like RTE, RTC, beverages, bakery

Yes. Central and State schemes support machinery, infrastructure, cold storage & logistics.

Absolutely. We assist in selection, customisation, layout planning & commissioning.

Usually 6–9 months, depending on scale, approvals & subsidy timelines.

Yes. FPOs often receive higher subsidy benefits and priority support.

Set Up Your Primary Processing Unit with Confidence

C2EX Consulting transforms raw agricultural produce into market-ready commodities—creating value for farmers, entrepreneurs & exporters.

-

+91 87480 71103

-

info@c2exconsulting.com

-

C2Ex Consulting No. 39/3, 1st Floor, Richmond Town Richmond Road, Bengaluru – 560025